hardware / firmware

hardware / firmware

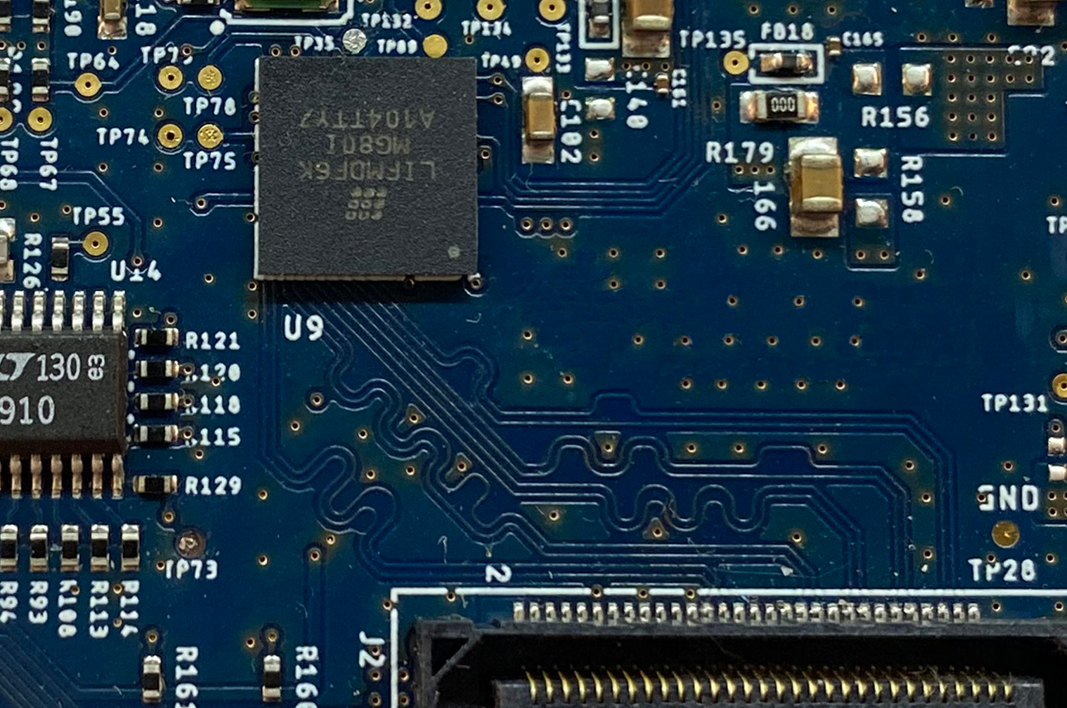

Florence Engineering designs electronic circuits of any type to meet the requirements of the most modern and advanced industrial applications. The company has the skills and tools to design and simulate the behavior of simple electronic boards or complex systems, taking into account electrical, thermal and mechanical constraints.

Florence Engineering has a well-equipped laboratory with the instrumentation for the development and testing of complex electronic boards and systems, including soldering and desoldering stations to manually and quickly carry out any changes that may become necessary.

The company has an internal team of firmware developers for the main microcontroller architectures and programmable logic, and is able to provide the customer with the finished, tested and functioning product, ready to be put into operation.

Florence Engineering can also provide the customer with one or more prototypes of what is designed, whether it is a purely electronic or electromechanical system, thanks to a collaboration network with specialized companies able to provide parts in a short time and at reasonable prices.

Florence Engineering can also support the customer throughout the whole certification process of the electronic product, starting from the identification of the reference standards up to the interaction with the accredited laboratories and the drafting of the technical file.

The activity carried out by Florence Engineering is not limited to the design of the electronic board, but also extends to the related housings and containers, made to design or by adapting commercial products, both in plastic and metal. This is because very often the design of housing is an integral part of the electrical design, both for thermal reasons (heat dissipation) and for electromagnetic reasons (insulation between different parts of the circuit). Over the years, Florence Engineering has consolidated partnerships with mechanical companies for the production metal parts in a short time and even in small quantities. When necessary, Florence Engineering has the capability to produce 3D printed parts made from different plastic materials in-house or from external suppliers.

At the end of each project Florence Engineering provides all the documentation necessary to start production, leaving the customer free to contact their usual suppliers or may provide support even in the subsequent phases.

Over the years, Florence Engineering has developed the ability to adapt to different operational approaches: it is able to interact with companies far from the world of electronics, listening to the customer’s needs and supporting them from the definition of the specifications, or it can start from well-defined specifications, detailed and documented. In any case, the company is able to develop a product respecting pre-established deadlines and interfacing with the customer on a regular basis for updates on the progress of the activities.